Comparison of Cassava Grinding Machines for Starch and Garri Processing

FAQ / Chat online / Technical support / April 11, 2025

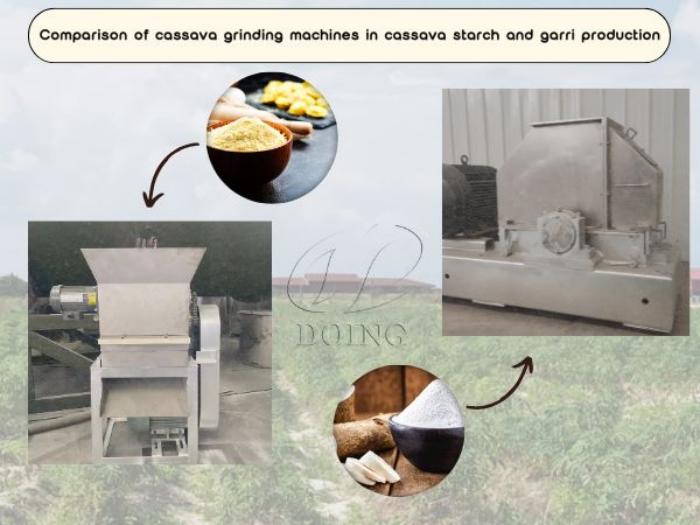

Cassava grinders play a key role in cassava processing. Due to the different structures of cassava grinders, the processing fields of cassava grinding machines are also different, such as the grinders in the production process of garri and cassava starch.

Today, Henan Jinrui, a professional cassava processing equipment supplier, will take the cassava grinding machines for starch and garri processing as an example for a comprehensive comparison, focusing on their application goals, design features and output characteristics.

1. Application of Different Grinding Machines

Different graters have different applications in cassava processing. For example, the grinding machines used in cassava starch processing include cutter and rasper, while the grinding machine used in garri processing only have cassava grater. Below is a detailed comparison of the application areas of cassava grinding machines in starch and garri processing.

Application of different cassava grinding machines

Application of different cassava grinding machines

Cutter and Rasper for Starch Production

In starch production, the main goal is to efficiently extract the maximum amount of starch from cassava roots. Therefore, we need to use appropriate cassava processing equipment during the grinding process so that the cassava is fully ground to release a large amount of starch to increase the yield of starch processing. Cutter and rasper are commonly used grinding equipment in the starch processing. The combination of the two can increase the grinding rate of cassava tubers. For example, using the cutter and rasper designed by Henan Jinrui as cassava grinding equipment for the starch production can achieve a cassava grinding rate of 96%.

Cassava Grater for Garri Production

Garri production has different processing goals compared to starch production. For garri production, the choice of grinding machine needs to prioritize particle texture control during the fermentation and baking stages. The grinding process in garri production usually involves dry or semi-dry grinding. Conventional grinders are used, usually equipped with toothed rollers or using a hammer mill mechanism. These grinders are designed to break the cassava into uniform coarse particles.

2. Comparison of Key Components of Cassava Grinding Machine

Above we have compared in detail the application of cassava grinding machines in garri and starch production. The reason why cassava grinders are used in different scenarios is because of the different equipment structures. The following table compares the key components of grinding machines in the production of starch and garri.

| Feature | Rasper (Starch) | Grinder Machine (Garri) |

| Grinding Mechanism | High-speed rotating blades/raspers | Toothed rollers/hammer mills |

| Key Components | Pulping drum, saw blades etc. | Licker roller, toothed shaft etc. |

| Automation Level | Fully automated | Semi-automated (modular setup) |

3.Output Characteristic Comparison of Grinding Machines

Due to the different structures of cassava grinders, the characteristics of their output products are also different. The grinding equipment, cutter and rasper for starch processing usually output small particles of starch slurry, while the grinder for garri processing usually outputs larger cassava particles. The following is a comparison of the outputs processed by different cassava grinding machines.

Grinding machine for starch production

Grinding machine for starch production

Output in Starch Processing

The output of starch - processing grinding machines, like the Rasper mill, is a fine slurry. In this slurry, the starch is in a separated state, with particle sizes typically ≤100 µm. This fine particle size is essential as it allows for efficient separation of starch from other components in subsequent processing steps.

Output in Garri Processing

The output of garri - processing grinding machines is characterized by a coarse, granular texture. The particle size, as mentioned earlier, ranges from 0.5 - 2 mm. This size is ideal for fermentation. During fermentation, the larger surface area of these coarse granules allows for better interaction with the microorganisms involved in the fermentation process. After fermentation, the sieving - friendly size of the granules makes it easy to separate any under - or over - sized particles, ensuring a consistent quality of the final garri product.

Grinding machine for garri production

Grinding machine for garri production

In conclusion, by the detailed comparison, cassava grinding machines for starch and garri processing are distinct in their application, design and output characteristics. Starch - production grinding machines, like the rasper, are optimized for high - efficiency starch extraction through wet grinding, with a focus on fine - particle - size output and large - scale, automated processing. Garri - processing grinding machines, on the other hand, are designed to achieve a specific granular texture through dry or semi - dry grinding, with a modular and often semi - automated setup suitable for the unique requirements of garri production.

Comparing these differences of cassava grinding machines is crucial for entrepreneurs, processors, and investors in the cassava - processing industry, as it enables them to make informed decisions when setting up or upgrading their cassava processing operations. If you have any demand for cassava grinding machines, welcome to consult us! Henan Jinrui will provide you with high quality equipment and best service!

contact us

- Do you want to buy machine?

- Yes, I want to buy machine

- No, I want to learn more in advance.

- What is your raw material?

- Cassava

- Potato

- Sweet potato

- Others

- 2. What is the final product you want to produce?

- Garri

- Cassava flour

- Cassava starch

- Cassava chips

- Attiekie

- Bammy

- Others

- 3.What is your capacity plan?

- Small scale garri machine

- 1ton per day

- 2tons per day

- 3tons per day

- 10tons per day

- 20tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

- 3.What is your capacity plan?

- Small scale

- Middle type

- Large scale

- What is your capacity plan?

- Small scale

- 5tons per day

- 10tons per day

- 20tons per day

- 50tons per day

- 100tons per day

- 200tons per day

- 300tons per day

- Others

Call us

Call us Chat online

Chat online